Why Is It Important to Determine the Size of Insulated Panels?

In construction, choosing the correct insulated panel size plays a critical role, directly affecting construction quality, cost efficiency, and project timelines. Each type of project-such as factories, cold storage facilities, cleanrooms, or modular offices-has its own technical requirements. Therefore, accurately determining the panel’s length, width, and thickness is an essential step that should not be overlooked.

Choosing the correct insulated panel size helps optimize thermal insulation, reduce costs, and ensure construction progress stays on schedule.

First and foremost, choosing the appropriate panel size helps optimize thermal insulation and soundproofing performance. Insulated panels with proper thickness and standard proportions minimize gaps, reduce heat loss, and help maintain a cool indoor environment in summer and warmth in winter.

In addition, selecting the correct panel specifications helps reduce material costs, as fewer joints are required, minimizing waste during cutting and installation.

Moreover, standard panel sizes contribute to structural durability and overall aesthetics. Uniform panels with fewer joints create a clean, solid surface that remains strong and visually appealing over time.

For these reasons, determining the insulated panel size from the very beginning is a crucial step in achieving optimal performance for any construction project.

How Many Types of Insulated Panels Are There? Structure of Insulated Panels

Today, insulated panels are manufactured in various types to meet different usage requirements. The four most common types include EPS panels, PU/PIR panels, Rockwool panels, and Glasswool panels. Each type has its own specific characteristics, allowing users to choose the most suitable panel for factories, cold storage facilities, cleanrooms, or residential construction projects.

All insulated panels currently available on the market are produced based on a common structure consisting of three tightly bonded layers: metal sheet – insulation core – metal sheet. This design not only provides structural protection but also maximizes thermal insulation, sound insulation, and fire resistance performance, as detailed below.

The insulated panel structure, consisting of two metal sheets and an insulation core, enhances durability and improves heat resistance.

Surface Metal Sheet Layer

The outer surfaces of insulated panels are typically made of aluminum-zinc alloy coated steel sheets with electrostatic painting, offering excellent resistance to oxidation, corrosion, and enhanced durability for construction projects. In high-standard applications, this metal layer can be replaced with stainless steel.

The metal surface comes in various designs, including flat panels, ribbed profiles for added strength, or color-coated finishes to meet aesthetic requirements.

Insulation Core Layer

This layer is the key component that determines the panel’s primary performance and is made from different insulation materials, including:

- EPS Foam: Lightweight, cost-effective, and provides stable thermal and sound insulation. Fire-retardant black EPS is also available.

- PU Foam: Features a closed-cell structure with high thermal insulation efficiency and lightweight properties.

- Rockwool: Made from light brown mineral fibers, known for excellent fire resistance and superior sound insulation.

- Glasswool: Composed of yellow fiberglass fibers, offering effective thermal insulation and commonly used in cleanroom applications.

Specialized Bonding Adhesive

The two metal sheets and the insulation core are firmly bonded together using specialized adhesive, ensuring strong structural integrity, preventing delamination during use, and extending the panel’s service life.

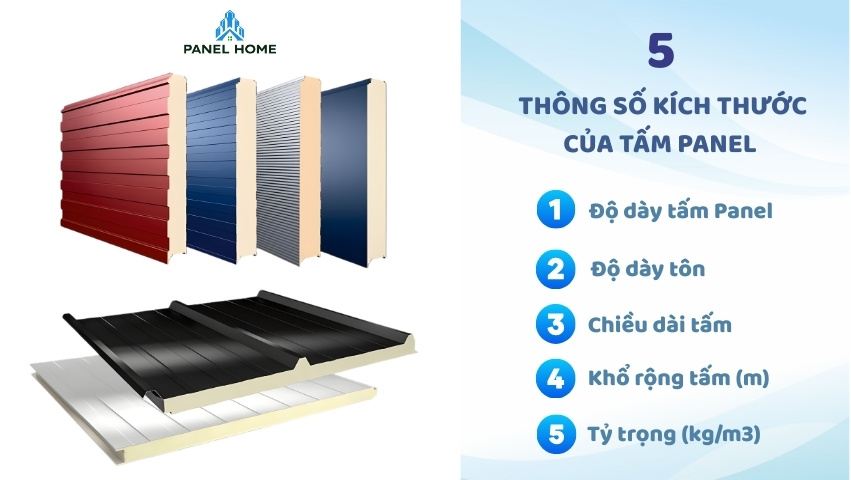

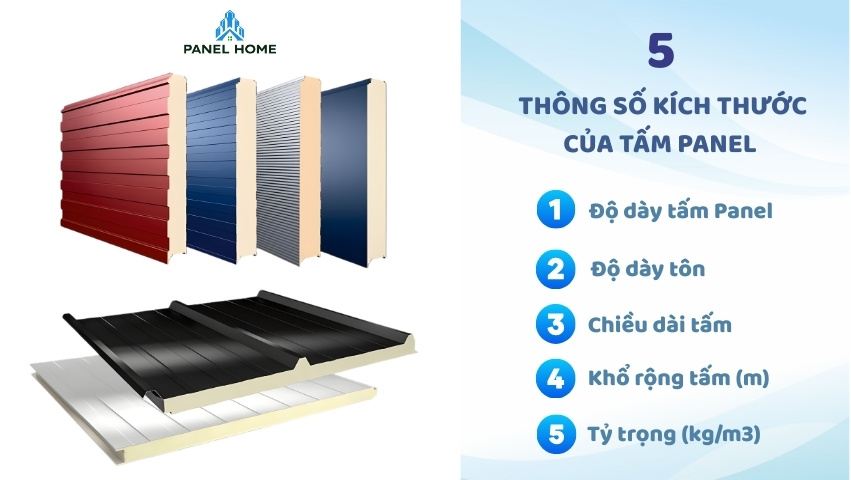

5 Key Specifications and Dimensions of Insulated Panels

The size of insulated panels is not fixed and varies depending on the product type and specific project requirements. However, there are several important technical specifications that users should clearly understand before installation:

5 Standard Dimensional Specifications of Common Insulated Panel Types Today

1. Panel thickness (cm):

The distance from the top steel sheet to the bottom steel sheet, determining the panel’s sound insulation, thermal insulation, and fire-resistance performance.

2. Steel sheet thickness (mm):

The thickness of each surface steel layer, which can be the same or different on each side depending on project requirements.

3. Panel length (m):

Manufactured according to actual project needs (custom-cut) to minimize joints. Common lengths range from 2.7 m to 5 m, with custom orders available up to 18,000 mm.

4. Panel width (m):

Includes two types:

- Product width: Total width including the joint/locking system.

- Effective width: The actual usable width after installation.

5. Density (kg/m³):

5. Density (kg/m³):

The density of the core material (EPS, PU, PIR, Rockwool, Glasswool, etc.), which directly affects the panel’s weight, durability, and load-bearing capacity.

Each insulated panel type – EPS, PU, PIR, or Rockwool – has its own set of specifications tailored to specific applications such as cold storage, clean rooms, factories, or residential buildings. Understanding panel dimensions and technical specifications helps investors choose the right product, optimize costs, and ensure long-term structural durability.

Types of Insulated Panels and Common Standard Dimensions

4 Common Types of Insulated Panels Today

4 loại tấm panel cách nhiệt phổ biến trên thị trường hiện nay

-

EPS Panels: This type of panel is lightweight, cost-effective, and easy to install. Thanks to these characteristics, EPS panels are commonly used for factories, storage warehouses, temporary structures, or projects that require rapid completion

-

PU Panels: Known for excellent thermal and sound insulation as well as high durability, PU panels also offer good moisture resistance. They are especially suitable for projects requiring a stable environment, such as cleanrooms, cold storage facilities, and food processing plants.

-

Rockwool Panels: The main advantage of Rockwool panels is their superior fire resistance and effective sound insulation. Therefore, they are often chosen for projects with strict fire safety requirements, such as large-scale factories or industrial workshops.

-

Glasswool Panels: With a balanced combination of thermal insulation, sound insulation, and fire resistance, Glasswool panels are widely used in technical rooms, substations, or areas with high noise levels. They help maintain stable temperatures and reduce noise in the building.

Summary of Panel Sizes by Category

1. Interior Wall Panel Sizes

| Panel Type |

Width (mm) |

Length (mm) |

Core Thickness (mm) |

Steel Sheet Thickness (mm) |

Density (kg/m³) |

Notes |

| EPS Panel |

1,000 |

2,000 – 18,000 |

50, 75, 100, 125, 150, 200 |

0.3 – 0.8 |

8–25 |

Lightweight, cost-effective, fast installation |

| PU Panel |

1,065 |

2,000 – 18,000 |

50, 75, 100, 125, 150, 200 |

0.4 – 0.8 |

38–40 ± 3 |

High thermal insulation, suitable for cleanrooms |

| Glasswool Panel |

1,065 |

2,000 – 18,000 |

50, 75, 100, 125, 150, 200 |

0.4 – 0.8 |

40–64 |

Good sound insulation, excellent fire resistance |

| Rockwool Panel |

1,065 |

2,000 – 18,000 |

50, 75, 100, 125, 150, 200 |

0.4 – 0.8 |

60–120 |

Superior fire resistance |

2. Exterior Wall Panel Sizes

| Panel Type |

Effective Width (mm) |

Length (mm) |

Common Thickness (mm) |

Steel Sheet Thickness (mm) |

Density (kg/m³) |

Notes |

| EPS Panel |

1,000 |

2,000 – 18,000 |

50, 75, 100 |

0.4 – 0.8 |

10–25 |

Commonly used for factories |

| PU Panel |

1,000 |

2,000 – 18,000 |

50, 75, 100 |

0.4 – 0.8 |

40 ± 3 |

Good thermal insulation and moisture resistance |

| Glasswool Panel |

1,000 |

2,000 – 18,000 |

50, 75, 100 |

0.4 – 0.8 |

40–64 |

Effective noise reduction |

| Rockwool Panel |

1,000 |

2,000 – 18,000 |

50, 75, 100 |

0.4 – 0.8 |

≥ 90 |

High fire safety requirement |

3. Roof Panel Sizes

| Panel Type |

Effective Width (mm) |

Length (mm) |

Core Thickness (mm) |

Steel Sheet Thickness (mm) |

Density (kg/m³) |

| EPS Roof Panel (5-wave) |

1,000 |

Transportable length |

50 – 200 |

0.4 – 0.8 |

8~25 |

| PU Roof Panel (2-wave) |

1,000 |

Transportable length |

10, 15, 20, 25, 30, 40, 50, 60 |

0.35 – 0.5 |

38 ± 3 |

| PU Roof Panel (5-wave) |

1,000 |

Transportable length |

20, 40, 50, 60 |

0.35 – 0.5 |

38 ± 3 |

| PU Roof Panel (11-wave) |

1,000 |

Transportable length |

10, 15, 20, 25, 30, 40, 50, 60 |

0.35 – 0.5 |

35~38 |

Some Important Notes When Purchasing Insulated Panels

To select the most suitable insulated panels and ensure effective installation, keep the following key points in mind:

1. Determine the purpose of use

Depending on the type of project-whether it is a factory, cold storage, cleanroom, or residential building-choose the appropriate panel type and size to optimize cost efficiency and functionality.

2. Choose panel thickness based on thermal and sound insulation requirements

For projects that require good thermal and sound insulation, prioritize panels with a thickness of 75-100 mm (7.5-10 cm) to ensure long-term and stable performance.

3. Pay Attention to Steel Sheet Thickness for Outdoor Projects

For outdoor installations that require high load-bearing capacity, thermal resistance, and durability, select panels with a steel sheet thickness of 0.4–0.5 mm to increase stiffness, minimize deformation, and extend the service life of the structure.

4. Consider Panel Density According to Structural Requirements

Avoid using panels with excessively high density for projects that require lightweight construction, such as renovating old houses, ceiling installations, or structures with weak frames, to ensure safety and reduce stress on the supporting structure.

5. Consider Aesthetic Factors

The color and surface design of panels (ribbed or flat) should match the overall architectural design of the project.

6. Choose the Appropriate Panel Thickness for Cold Storage Based on Storage Temperature

For cold storage facilities, panel thickness should be selected according to the intended temperature:

- Frozen storage (-18°C): Use panels with 100-150 mm thickness.

- Chilled storage (0-5°C): Panels with 75-100 mm thickness are suitable.

- Standard storage (10-15°C): Panels with 50-75 mm thickness can be used.

7. Measure Panel Dimensions Carefully Before Ordering

Each project requires different panel dimensions. Accurately measuring the height, width, and installation area will help prevent material shortages or excess, shorten installation time, and optimize costs.

Conclusion:

From the analysis above, it is clear that each type of panel has its own specifications, suitable for different applications ranging from residential buildings, factories, cold storage facilities, to cleanrooms. If you are planning a construction project, carefully consider the panel’s thickness, length, and width to optimize thermal and sound insulation performance as well as its long-term durability.

Panel Home – Supplier and Installer of High-Quality Insulated Panels with Standard Technical Dimensions

With many years of experience in the panel industry, Panel Home proudly provides high-quality insulated panels with transparent pricing and professional services. Contact us today at hotline 0901149298 – 0788 365 999 or visit Panelhome.com.vn for detailed consultation and the latest quotes!

5. Density (kg/m³):

5. Density (kg/m³):