Fire-Resistant Sandwich Panels – A Safe Solution for Modern Buildings

In the construction industry, fire-resistant sandwich panels are increasingly favored thanks to their ability to protect buildings from high temperatures and fire hazards. This advanced building material not only offers excellent thermal insulation and soundproofing performance, but also helps maintain a cool indoor environment in summer and warmth during winter.

More importantly, the use of fire-resistant panels contributes to energy efficiency, helping reduce operating costs while extending the overall lifespan of the building. With growing demands for fire safety and sustainable construction, fire-resistant sandwich panels have become an essential solution for both residential and industrial projects.

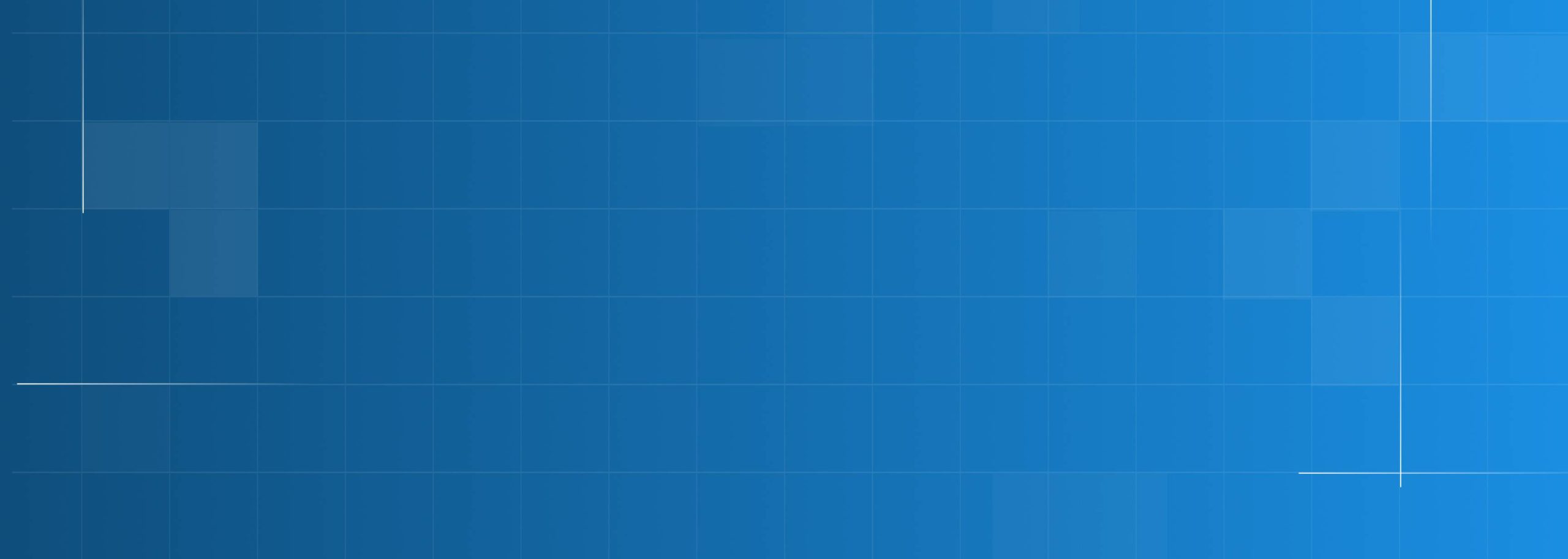

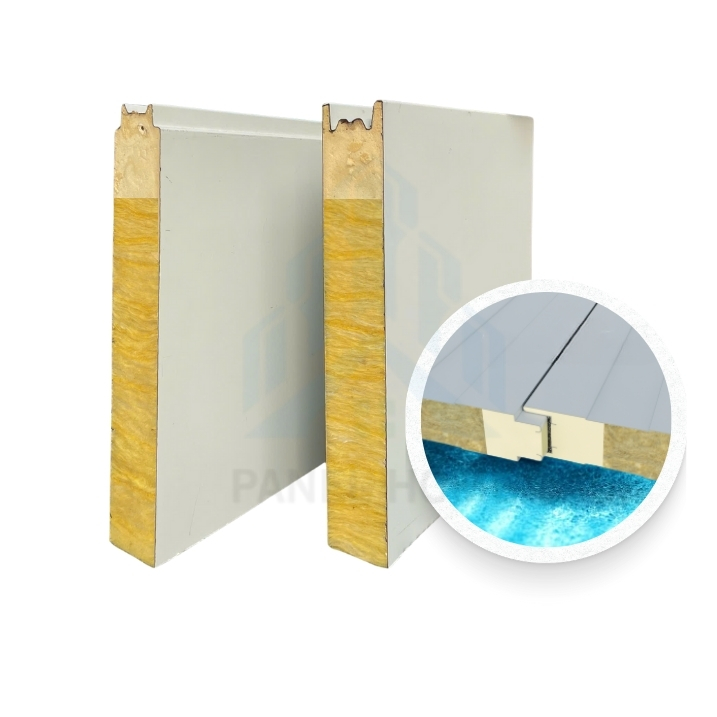

Fire-resistant sandwich panels meeting fire safety standards for residential and industrial buildings

Today, fire-resistant sandwich panels are widely applied across various construction sectors:

- Factories and industrial zones: Used for exterior walls, roofing, and partitions to reduce fire risks and ensure production safety.

- Cold storage and clean rooms: Help maintain stable temperatures, improve preservation efficiency, and reduce energy costs.

- Office buildings and shopping centers: Create fire-rated partition systems, enhance sound insulation, and provide quiet working environments.

- Hospitals and schools: Ensure a safe environment, limit fire spread, and maintain the necessary level of quietness.

- Residential houses, homestays, and modular buildings: Fast installation, cost-effective construction, while still delivering a modern and aesthetic appearance.

With outstanding advantages in durability, flexibility, and fire resistance, fire-resistant panels are becoming the optimal choice for projects ranging from residential to industrial applications. They represent a sustainable, safe, and environmentally friendly construction solution in today’s building trends.

What is the EI fire resistance standard?

The EI standard is a set of regulations used to evaluate the fire resistance performance of building materials, issued by fire safety authorities. EI stands for Integrity and Insulation:

- E – Integrity: The material maintains its structural integrity when exposed to fire, without cracking, deformation, or creating openings. This criterion is strictly tested to prevent flames and smoke from spreading to adjacent areas.

- I – Insulation: The material maintains stable thermal resistance, with the surface not being damaged by high temperatures, helping to limit fire spread and protect the building structure.

In other words, the EI standard is a critical benchmark for determining a material’s fire resistance capability, testing duration, and fire exposure limits, ensuring overall building safety and long-term durability.

EI-rated fire-resistant sandwich panels

EI-rated fire-resistant sandwich panels are panels that have undergone rigorous testing, trials, and certification processes. They fully comply with EI standard requirements before being approved for use in construction projects.

EI-rated fire-resistant panels help prevent fire spread and protect building structures.

Key advantages of EI-rated fire-resistant sandwich panels:

- Effective fire resistance and fire spread prevention over extended periods.

- Excellent thermal insulation, protecting buildings from high-temperature exposure.

- Safer and more durable compared to conventional panels such as EPS, PU, and XPS.

As a result, EI-rated fire-resistant panels have become the top choice for projects requiring strict fire safety standards, including factories, cold storage facilities, hospitals, and residential buildings.

Fire resistance rating levels under the EI standard

Under the EI standard, materials are tested for their ability to maintain Integrity (E) and Insulation (I) for a specified period when directly exposed to fire. This duration typically ranges from 15 minutes to 150 minutes, clearly defined by each rating level:

- EI15: Fire resistance and insulation for a minimum of 15 minutes.

- EI30: Maintains integrity and insulation for 30 minutes.

- EI45: Fire protection performance lasting up to 45 minutes.

- EI60 – EI90 – EI120 – EI150 – EI180, etc.: Higher ratings with fire resistance durations from 1 hour to more than 3 hours.

Using EI-rated fire-resistant panels is considered a safe, sustainable, and long-term solution for all types of buildings. This is also a growing trend among contractors and investors due to their ability to limit fire spread, protect structural integrity, and ensure human safety. Experts regard this as a worthwhile investment that helps buildings comply with fire safety regulations while extending their service life.

Fire resistance standards of common sandwich panels today

To ensure fire safety compliance, each type of fire-resistant sandwich panel must undergo testing and meet specific fire resistance standards. These regulations are used to evaluate heat resistance, fire spread limitation, and the ability to protect buildings in the event of a fire.

Fire resistance standards of PU sandwich panels

PU sandwich panels (Polyurethane) are widely used thanks to their lightweight structure, excellent thermal insulation, and basic fire-resistant performance. However, to enhance fire resistance, these panels are often manufactured with specialized fire-retardant additives.

- Fire resistance: Rated B2 or B3, meaning the material is difficult to ignite and can self-extinguish once the heat source is removed.

- Applications: Suitable for cold storage facilities, manufacturing factories, mobile offices, and cost-sensitive construction projects.

- Advantages: Superior thermal insulation, lightweight design, fast installation, and reasonable cost, making them ideal for small to medium-scale projects.

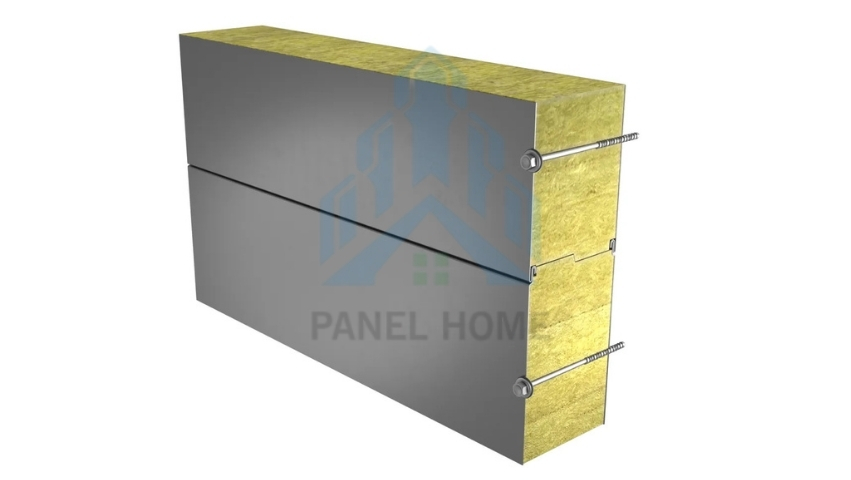

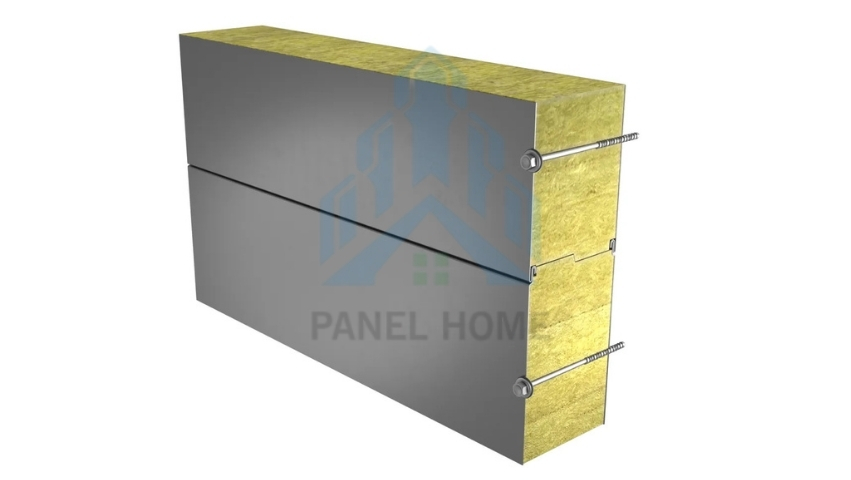

Fire resistance standards of Rockwool sandwich panels

Rockwool sandwich panels are a premium building material featuring a mineral wool core, well known for their ability to withstand temperatures of up to 1,000°C. Thanks to these superior properties, they are an ideal choice for projects requiring strict fire safety standards.

- Fire resistance standard: Rated A1 under EN 13501-1, classified as a non-combustible material.

- Applications: Suitable for factories, clean rooms, residential buildings, sound insulation systems, and projects requiring high-level fire protection.

- Advantages: Non-combustible, excellent thermal insulation, outstanding soundproofing performance, highly durable, and safe for human health.

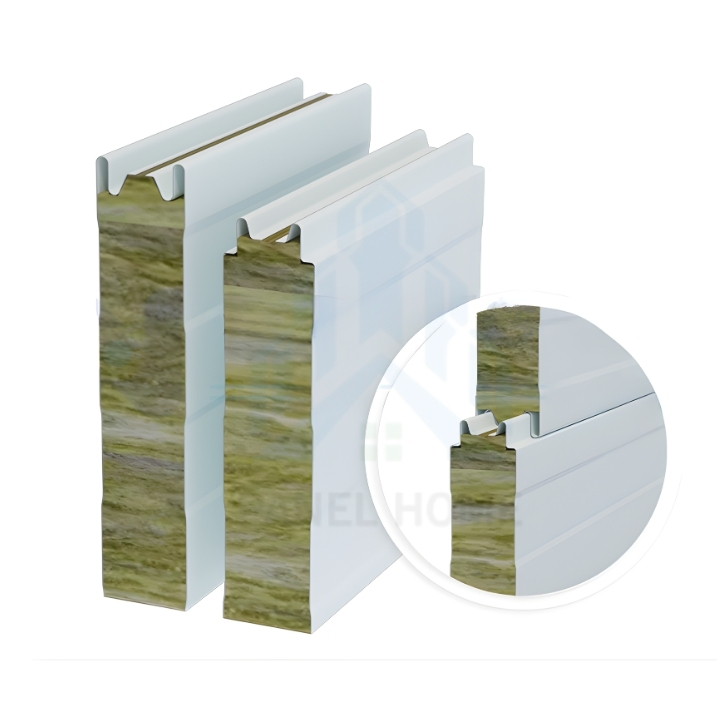

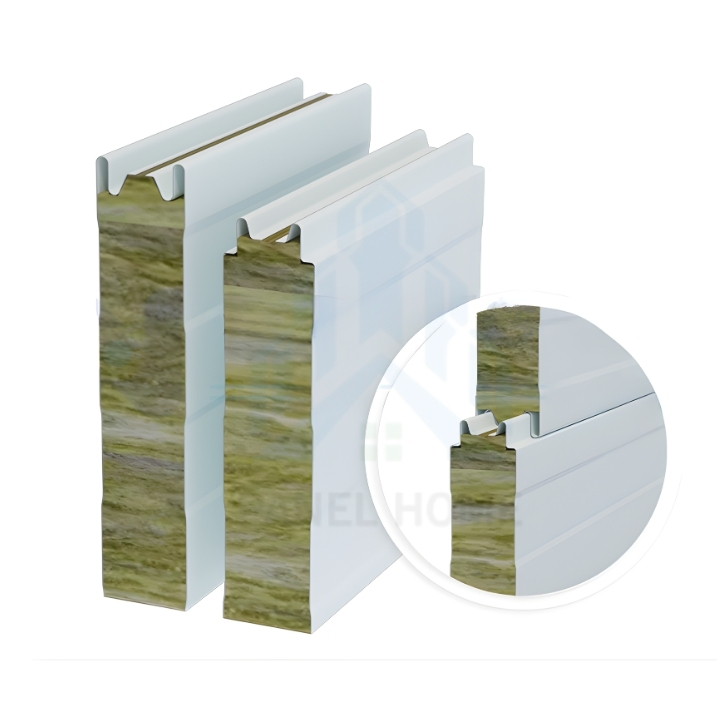

Fire resistance standards of Glasswool sandwich panels

Glasswool sandwich panels (fiberglass wool) are widely favored fire-resistant materials thanks to their excellent thermal insulation and high safety performance. The fiberglass core features slow ignition properties, helping reduce fire risks while enhancing the overall durability of buildings.

- Fire resistance standard: Rated A1 under EN 13501-1, classified as a non-combustible material.

- Applications: Commonly used in cold storage facilities, laboratories, manufacturing factories, and projects requiring strict temperature control.

- Advantages: Effective thermal insulation, non-combustible, good sound insulation, contributing to a safer and quieter environment.

Advantages of fire-resistant sandwich panels

Panel chống cháy giúp tăng an toàn, tiết kiệm năng lượng và chi phí thi công

Fire-resistant sandwich panels not only help minimize fire hazards but also deliver outstanding value in terms of thermal insulation, soundproofing, durability, and cost efficiency. As a result, they are increasingly trusted by investors, contractors, and businesses for projects ranging from residential to industrial construction.

- High fire resistance, withstanding temperatures from 600°C to 1,000°C, meeting international A1, A2, and B standards.

- Excellent thermal insulation, reducing energy loss and saving electricity for air conditioning systems and cold storage.

- Superior sound insulation, minimizing noise—ideal for recording rooms, hospitals, and offices.

- Strong and durable structure with galvanized steel or powder-coated aluminum skins, resistant to rust and corrosion.

- Lighter weight than concrete and brick, enabling faster installation and lower transportation costs.

- Long service life with minimal maintenance, helping reduce long-term construction and operating expenses.

Tips for choosing the right fire-resistant sandwich panel

In today’s market, fire-resistant sandwich panels are classified by core materials, fire resistance ratings, and fire safety certification standards. Each type of panel is designed for specific applications. Therefore, to select the right fire-resistant panel, investors should consider the following key criteria:

4 Popular Types of Fire-Resistant Insulation Panels on the Market Today

1. Identify the building’s intended use

For residential houses, homestays, and modular offices, priority should be given to panels with good thermal and sound insulation that are safe for occupants. B2-rated fire-resistant PU panels or Glasswool panels are suitable choices, offering reliable fire safety while maintaining a cool, quiet, and comfortable living environment.

For factories, industrial zones, cold storage facilities, clean rooms, and hospitals, higher fire safety standards are required. In these cases, Rockwool or Glasswool panels rated A1 are recommended. These panels can withstand temperatures from 600°C to 1,000°C, effectively limit fire spread, and fully comply with fire safety regulations.

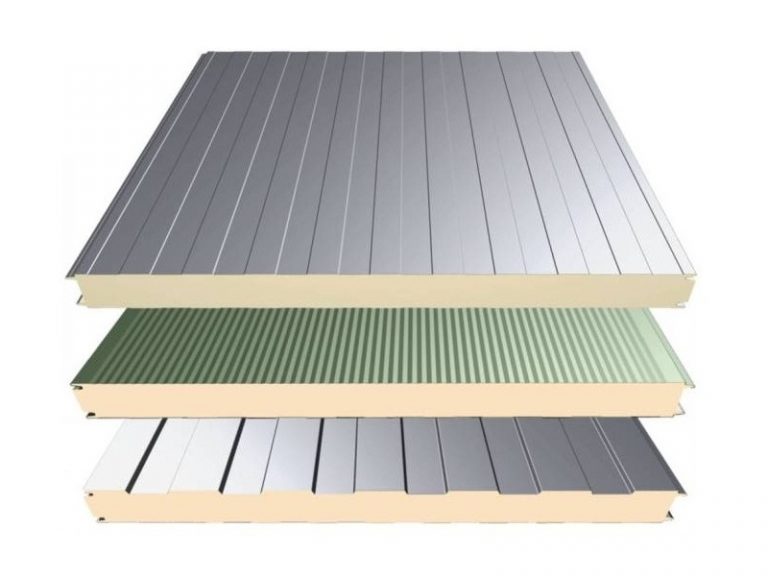

2. Choose the appropriate panel core material

- Fire-resistant EPS panels: Low cost, lightweight, suitable for temporary structures or budget-limited projects. Fire resistance is at a basic level.

- Fire-resistant PU panels: Excellent thermal insulation, B2 fire rating, suitable for cold storage, offices, and small to medium-sized factories.

- Fire-resistant Glasswool panels: Non-combustible, good sound insulation, A1 rated, ideal for clean rooms, factories, and technical buildings.

- Fire-resistant Rockwool panels: The highest level of fire protection, A1 rated, heat resistance up to 1,000°C, suitable for projects with strict fire safety requirements.

3. Pay attention to fire resistance standards (EI, A1, B2, etc.)

When selecting fire-resistant panels, always verify the EI rating or international fire classifications such as A1, A2, or B.

- Residential buildings typically require EI30 – EI60.

- Industrial facilities and large factories should use EI90 – EI120 or higher to ensure safety in the event of a fire.

4. Evaluate site and environmental conditions

In hot, humid, or high-rainfall areas, choose fire-resistant panels with galvanized steel or powder-coated aluminum skins. These materials offer excellent moisture resistance, corrosion protection, and longer service life, helping maintain structural durability over time.

5. Prioritize a reputable fire resistant panel supplier

Finally, select a supplier that provides certified fire-resistant panels with clear fire safety test reports and official documentation. Certified panels not only enhance building safety but also help avoid inspection rejections or costly replacements after installation.

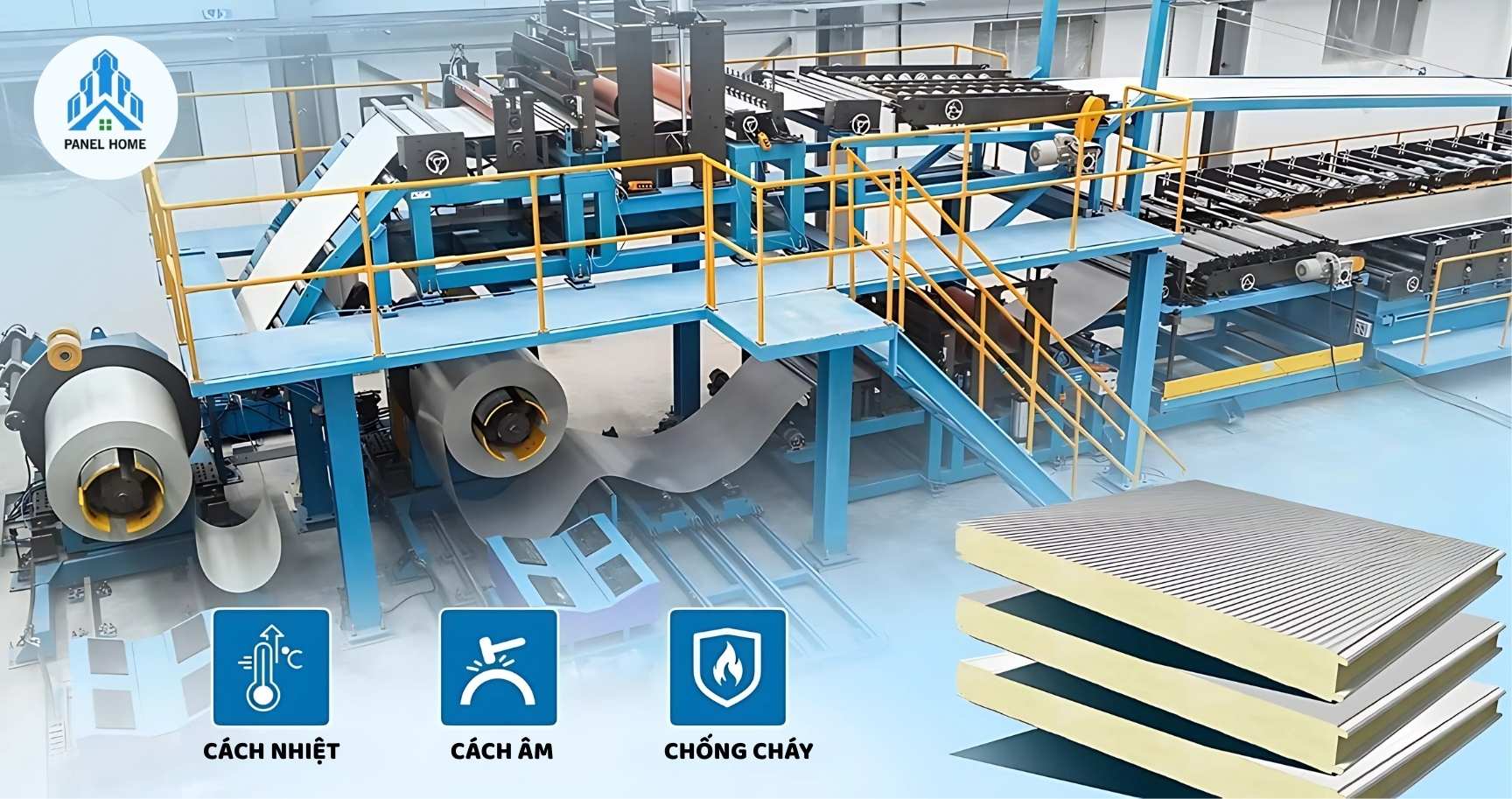

Reliable and top-quality fire resistant panel suppliers in Vietnam

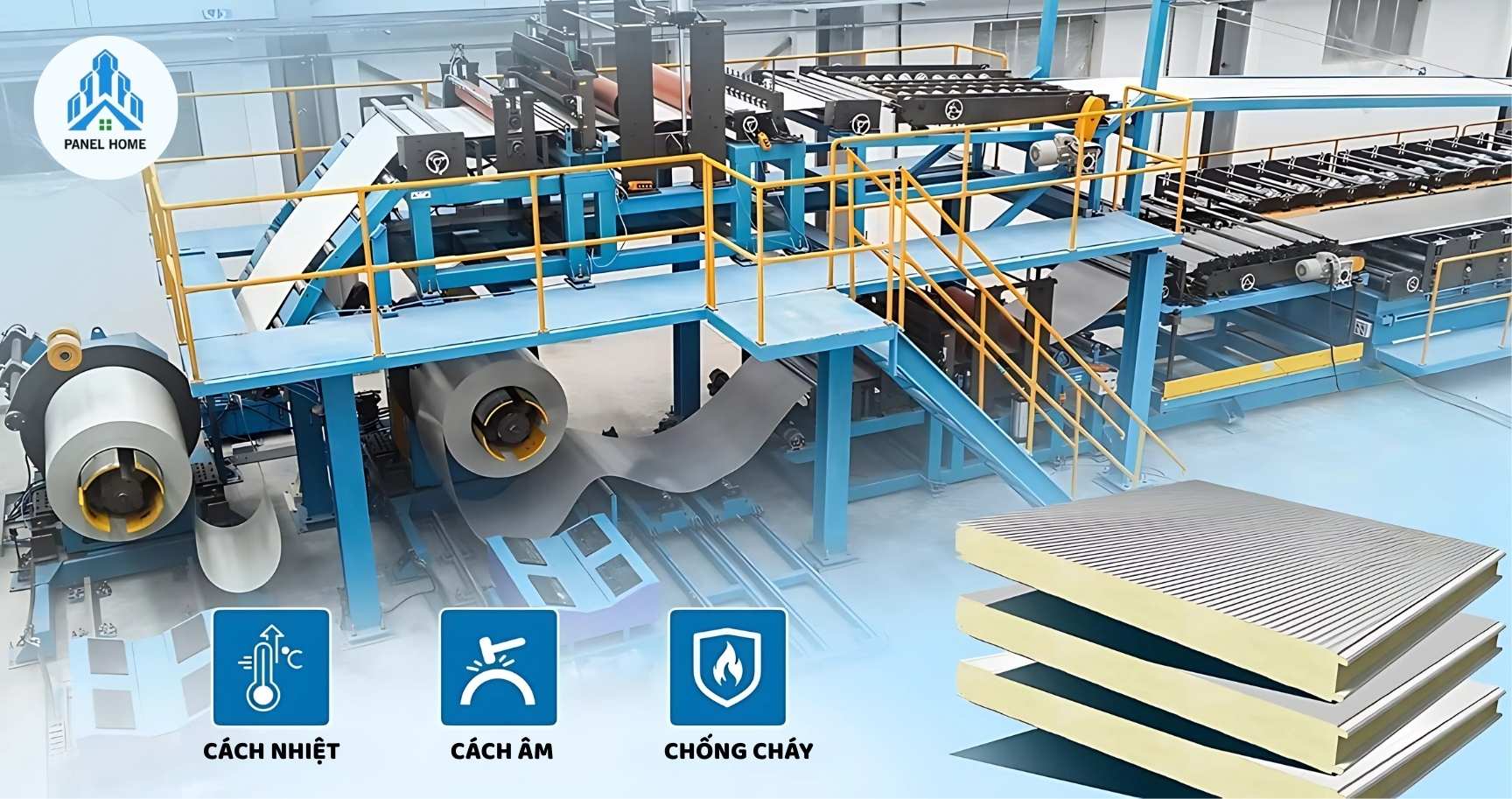

If you’re looking for a supplier of standard-compliant fire-resistant panels, Panel Home is a trusted choice. Our products are strictly manufactured and tested, ensuring reliable insulation, fire resistance, and durability, complete with QC certificates for investors.

Panel Home also provides professional after-sales service and technical support. Our experienced engineering team will recommend the right type of panel for each project, from residential homes to industrial developments.

With a reputation trusted by numerous businesses and contractors, Panel Home is your go-to source for high-quality fire-resistant panels.

📞 Contact our hotline at 0901149298 for detailed consultation and the best price quote.