What is soundproof material?

Soundproof material refers to specialized products used in projects that require a high level of sound insulation. Their function is to reduce the transmission of sound between two different spaces.

In physical terms, it means reducing the intensity of sound traveling from outside to inside and vice versa.

Today, soundproof materials are widely applied in most construction projects, especially those requiring quiet environments or producing loud noises such as:

- Factories, warehouses, offices, clean rooms

- Karaoke rooms, bars, nightclubs

- Residential areas, motels, bedrooms, restaurants, hotels

- Hospital operating rooms, laboratories, and special patient care rooms

Top 6 Best Soundproof Materials in 2022

Sound waves travel through solid, liquid, and air, but not through a vacuum. Based on this principle, people have created many types of materials capable of soundproofing and noise absorption.

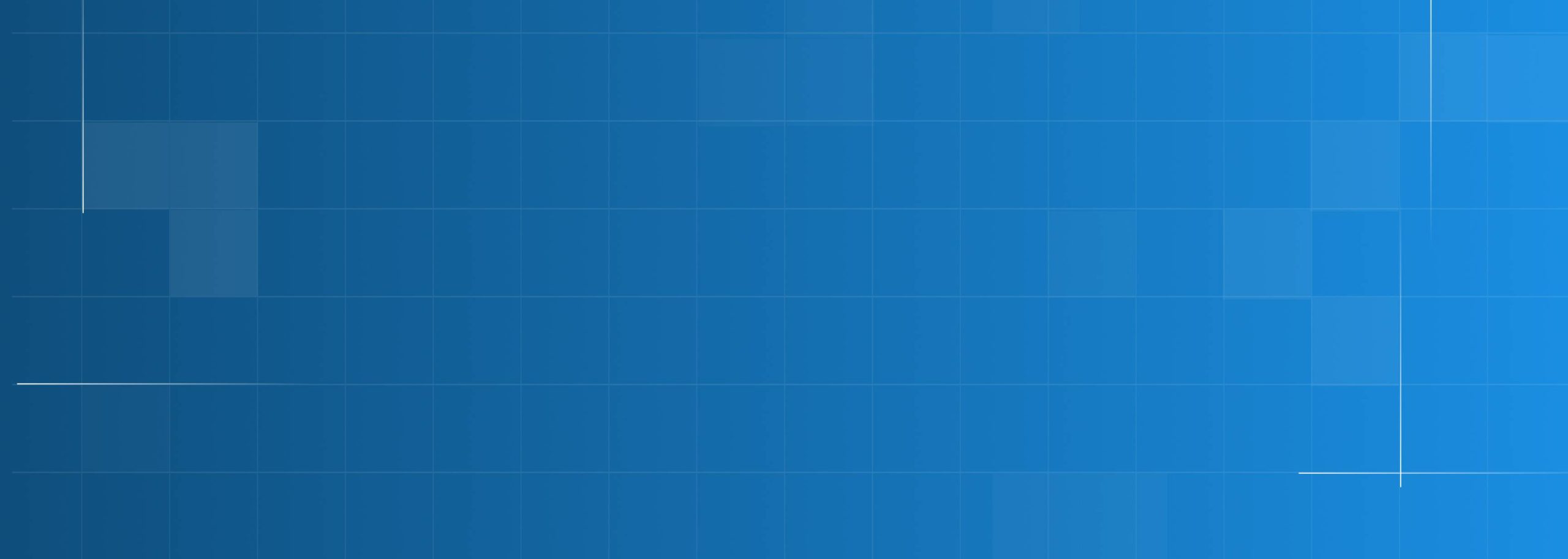

1. PU Panel

PU Panel is an extremely effective soundproof material with an average sound reduction capacity of over 27.3 dB, thanks to its polyurethane insulation core with a closed-cell density of up to 99%.

In addition to excellent sound insulation, PU panels also offer outstanding heat insulation, vibration resistance, and fire resistance. They are widely used in hospital operating rooms, special care rooms, laboratories, and clean rooms.

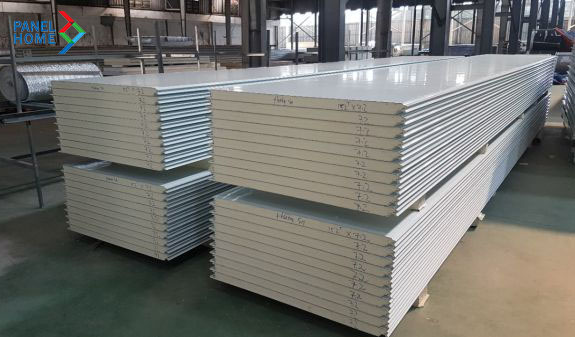

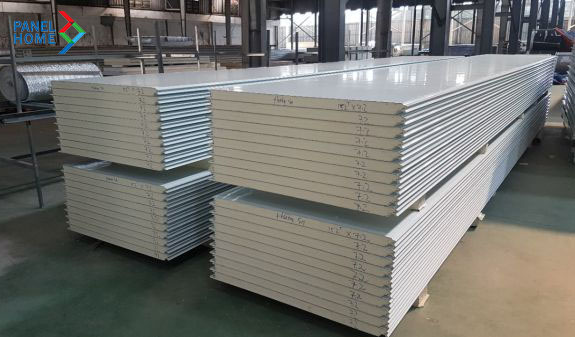

2. EPS Sound Insulation Panel

EPS panel is a lightweight construction material with a core made of Expandable Polystyrene (EPS) beads. After being heated and expanded, it becomes a compound containing Bentane gas (C5H12).

The composition of EPS beads consists of 90–95% Polystyrene and 5–10% foaming agents such as pentane or carbon dioxide. With such a composition, the foam core provides the project with perfect sound insulation with an average sound transmission coefficient of 25.01 dB.

Similar to PU panels, EPS panels also have good thermal insulation, lightweight, and low cost, making them widely used for all types of projects such as factory ceiling and wall panels, warehouses, restaurants, hotels, libraries, prefabricated houses, and field hospitals.

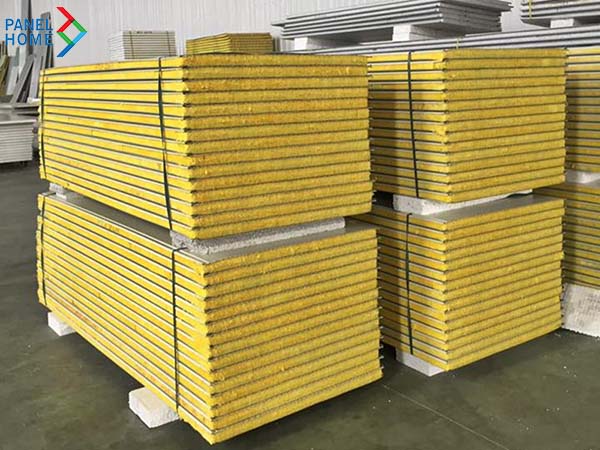

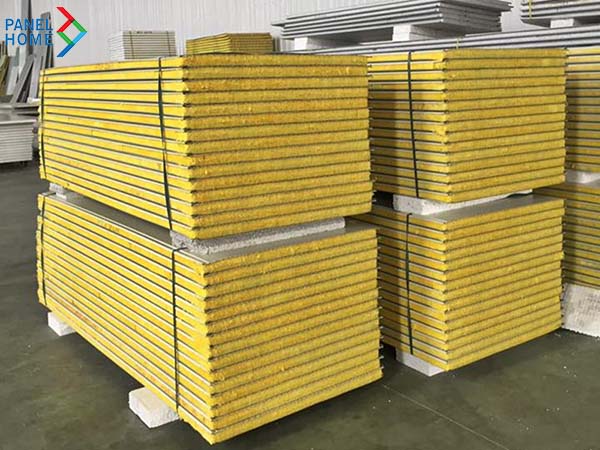

3. Glasswool Sound Insulation Panel

The third soundproofing material that Panel Home would like to introduce is the Glasswool Panel.

This product structure includes three layers: metal sheet – glasswool – metal sheet. The two outer surfaces are high-quality metal sheets with a thickness of about 0.3 mm – 0.5 mm.

The inner core is glass wool made mainly of Aluminum, Calcium Silicate, and Metal Oxides – free of Asbestos.

Tiny, uniform air layers between glass wool fibers help minimize sound transmission.

The Lambda coefficient is only 0.044 (W/mK), which significantly reduces sound waves passing through this panel.

In addition to sound insulation, glasswool panels also provide heat insulation and fire resistance for up to 2 hours, suitable for crowded residential areas, noisy neighborhoods, karaoke rooms, and nightclubs.

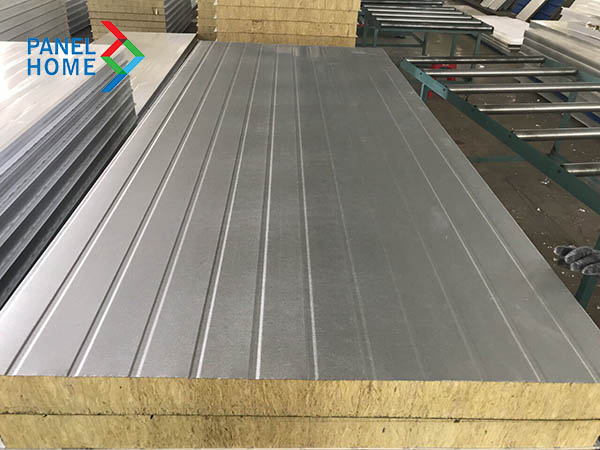

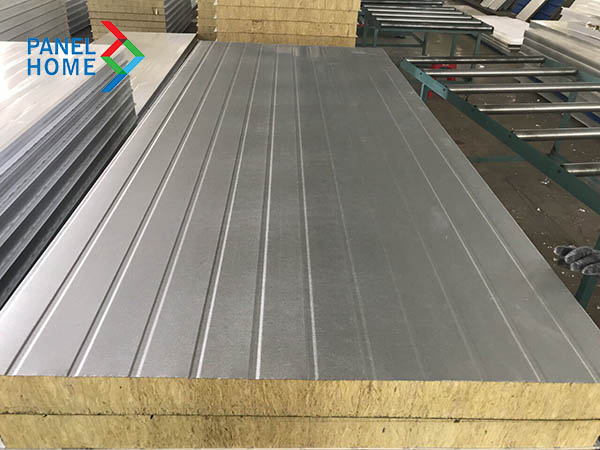

4. Rockwool Panel

Rockwool sound insulation panels are certainly familiar to investors due to their outstanding fire and sound resistance.

The mineral wool core is made from melted rock (at 1600°C) spun into small fibers combined with specialized chemicals to form Rockwool.

The Rockwool core is covered with two layers of galvanized and electrostatically painted metal sheets.

The components of this panel product are bonded with specialized adhesives, creating a panel with excellent sound and fire insulation.

Rockwool panels with fire, sound, and thermal resistance are suitable for various positions such as walls, partitions, and ceilings in residential, industrial, and laboratory buildings.

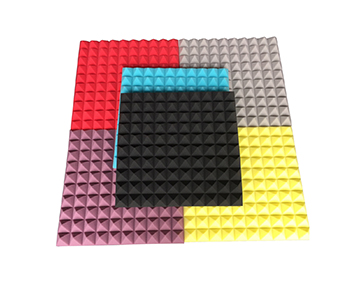

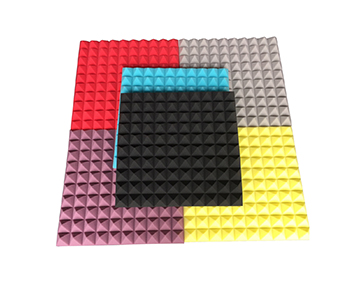

5. Acoustic Foam

Acoustic foam has a special structure — a foam layer with many tiny pores that can receive and completely absorb sound.

When sound hits the foam, it penetrates inside instead of bouncing back like when it hits walls or flat materials such as brick, concrete, or wood.

Acoustic foam has an uneven surface that easily absorbs sound, with an NRC (Noise Reduction Coefficient) of 0.95, capable of absorbing sound waves in many frequency ranges from 0.8 – 1.05Hz.

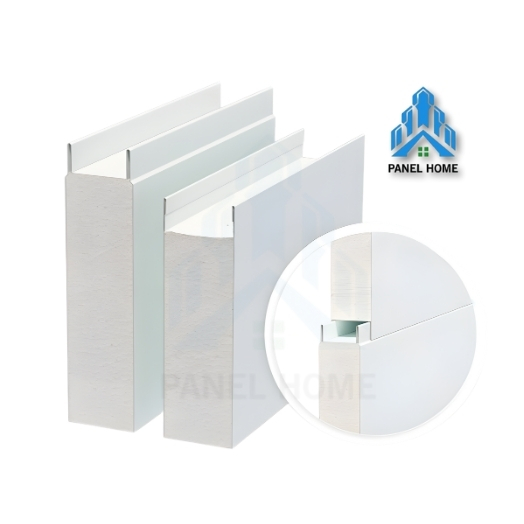

6. Soundproof Gasket

Soundproof gaskets are rubber gaskets used to seal gaps in doors and holes in windows and entrances.

They are also used to seal duct joints, preventing air from leaking through the joints.

The product is made from high-quality rubber materials and is often used with accessories for panel doors.

How to Use Soundproof Materials Properly?

Sound insulation materials provide soundproofing for the project.

However, customers should carefully consider before making a choice and pay attention to the following points:

- Pay attention to soundproofing both inside and outside the building for the best results.

- Avoid designing flat walls because they increase sound reflection. Therefore, buildings requiring high soundproofing should use rough wall surfaces.

- Choose soundproofing materials suitable for usage requirements while ensuring maximum cost savings.

- Buy soundproofing materials from reputable suppliers specializing in construction materials to get quality products at the best prices.

Reputable Soundproof Material Supplier in Northern Vietnam

Panel Home is the No.1 reputable soundproof material supplier in Northern Vietnam.

Currently, Panel Home is a leading distributor of soundproof materials on the market, offering a wide range of products and models.

All products originate from Panel Home’s panel manufacturing factory and are produced on modern European technology lines, ensuring high-quality products with excellent usability value.

Panel Home has carefully calculated and offered the most competitive prices on the market, providing detailed, accurate, and quick quotations.

Currently, Panel Home is running a promotion of up to 30% discount on orders to celebrate its 14th anniversary.

Customers interested in Panel Home’s soundproof materials, please contact hotline 0788 365 999 – 0971 928 666 to become one of the first 500 lucky customers to receive special offers from the company.